Description

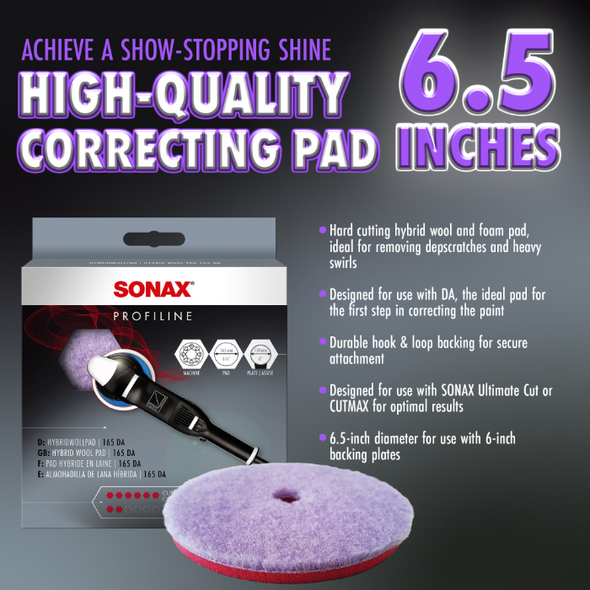

The Sonax Hybrid Wool Pad 80 DA (3 inch, pack of 2) features a blend of natural lambswool and polyester for effective cutting on orbital polishers. Designed to tackle deeper scratches and heavy paint defects, these pads provide high abrasion without overheating or splashing. Their compact 76.2mm size fits smaller backing plates, making them ideal for precision work on tight areas. Durable and efficient, this set is perfect for professionals and enthusiasts aiming for expert paint correction results.

Achieve superior paint correction results thanks to the pad's high-tech composition. The unique mixture of natural lambswool provides exceptional cutting action, while the inclusion of polyester ensures the pad maintains structural integrity and dissipates heat effectively. This combination allows for rapid defect removal—even the deepest scratches—without the risk of overheating the panel or creating messy compound splatter, ensuring a cleaner and safer polishing process.

Specifically designed with an 80 mm diameter to pair perfectly with 75 mm backing plates on your orbital polisher. This size is ideal for targeting smaller, complex body panels, tight areas, and spot repair work where larger pads cannot reach. The precise fit and material integrity guarantee optimal transfer of the polisher's orbital motion, maximizing correction efficiency and providing consistent results across the entire working area.

For best results and to ensure the longevity of your pad, please follow these steps carefully:

Preparation & Mounting:

-

Inspect the Pad: Before each use, ensure the pad is clean and free of any foreign particles that could scratch the paint.

-

Mount the Pad: Center the 80 mm polishing pad precisely onto your orbital polishing machine's 75 mm backing plate using the hook-and-loop system. A centered pad is crucial for smooth, balanced operation.

Compounding Process:

-

Prime the Pad (Initial Use Only): Apply 2-3 dime-sized drops of a high-performance cutting compound, such as SONAX PROFILINE ExCut 05-05, around the outer edge of the pad. Work the product into the wool/polyester mixture with your finger or a light touch to the paint to lightly prime the pad face.

-

Work Area: Work on a small section of paint (approx. 12 x 12 inches) at a time.

-

Polishing: Place the pad flush against the paint surface before turning on the polisher. Start the machine on a low speed (e.g., speed 1-2) to spread the compound, then increase to your working speed (e.g., speed 3-5).

-

Maintain Technique: Use a slow arm speed and moderate, consistent downward pressure. Move the polisher in overlapping passes (cross-hatch pattern). Crucially, do not apply high pressure or tilt the pad excessively, as this can damage the pad and potentially burn the paint.

-

Monitor Temperature: Constantly check the temperature of the working area with your hand. Do not allow the polishing area to overheat. If the surface feels hot to the touch, stop immediately and move to a new section.

Cleaning and Maintenance:

-

Regular Blow-Out: During the polishing session, the pad will "load up" with spent polish and paint residue. Regularly stop the machine and blow out the pad's abrasive surface with compressed air to clear the fibers and maintain cutting efficiency.

-

Post-Use Cleaning: After your detailing session, clean the pad thoroughly. We recommend using a dedicated pad cleaner, such as DP Polishing Pad Cleaner or Snappy Clean Pad Cleaning Powder, and a Pad Cleaning Brush or a specialized pad washing system like the Grit Guard Universal Pad Washer.

-

Drying & Storage: Rinse all cleaning residue completely from the pad and allow it to air-dry naturally, face-up. Never use a high-heat dryer. Store the dry pad in a clean, dust-free environment. Never use different compounds or polishes on the same pad.